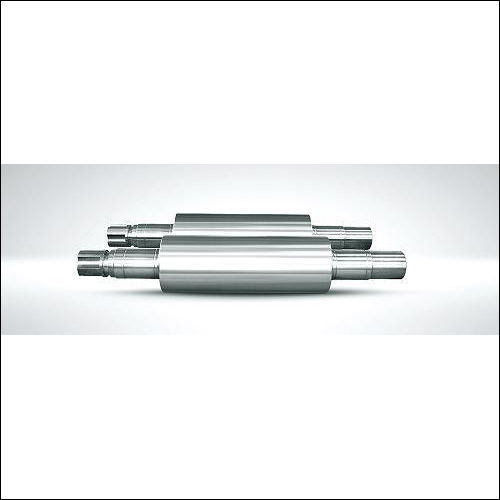

Tungsten Carbide Roll Rings

Product Details:

- Diameter 100 mm to 450 mm

- Capacity Customized as per application

- Material Tungsten Carbide

- Dimensions As per requirements/drawing

- Technique Hot and Cold Isostatic Pressing (HIP/CIP), precision grinding

- Standard ISO 9001:2015

- Belt Width Up to 150 mm

- Click to View more

Tungsten Carbide Roll Rings Product Specifications

- Up to 150 mm

- Hot and Cold Isostatic Pressing (HIP/CIP), precision grinding

- High wear resistance, excellent toughness, precise dimensions

- ISO 9001:2015

- Tungsten Carbide

- As per requirements/drawing

- Customized as per application

- 100 mm to 450 mm

- HRA 78-90

- 13.9 - 14.5 g/cm³

- Extended usage: 5-6 times longer than traditional rolls

- Excellent

- Round, oval, or custom profiles

- Wire rod, rebar, seamless tube and bar rolling mills

- Up to 900°C working temperature

- ±0.01 mm

- Solid or with steel core

- Polished, mirror or matte

Product Description

In todays rolling processes, Tungsten Carbide Roll Rings have become an important part of several industries. Being reliable products, these are strong enough to perform different performance. New grades of materials and modern day machine are used along for the manufacturing of this range in tandem with the industrial laid norms. Available in different specifications, these rings are checked on different quality constraints under the proper vigilance of our experts. Tungsten Carbide Roll Rings are easily accessible to our clients at industry leading prices.

Key features:

- Excellent surface finish

- Durable quality

- Easy maintenance

YGH-T series of roll rings

Prosperties

| Grade | Chemical composition | Mechanical properties | Substitute for other carbide grade for roll rings | |||||

| Co+Ni% | WC% | Hardness (HRA) | Transverse bending strength (sample B) (MPa) | Density (g/cm3) | | Cerametal | Sintermet | |

| YGH10T | 6 | 94 | 88 | 2250 | 14.9 | H6T | CE65 | SM80 |

| YGH20T | 12 | 88 | 86 | 2750 | 14.3 | | | SM64 |

| YGH30T | 15 | 85 | 85 | 2800 | 14 | H15C | CE79 | SM59 |

| YGH40T | 18 | 82 | 83 | 2700 | 13.7 | | CE103 | SM65 |

| YGH50T | 22 | 78 | 82 | 2700 | 13.4 | H25P | CE112 | SM61 |

| YGH60T | 30 | 70 | 79 | 2500 | 12.7 | C30P | CE260 | SM62 |

Superior Wear and Thermal Resistance

Thanks to their advanced tungsten carbide composition and manufacturing through HIP/CIP, these roll rings exhibit remarkable wear resistance and toughness. Capable of consistent performance at temperatures up to 900C and resisting harsh mill environments, they minimize downtime and extend operating cycles. Their corrosion-resistant qualities further ensure stable, long-term operation in demanding rolling mill applications.

Customizable for Diverse Applications

Available in round, oval, or custom profiles, with core options (solid or steel-core), and tailored dimensions (diameter 100450 mm, belt width up to 150 mm), these roll rings suit a broad variety of mill setups. Whether polished, matte, or mirror-finished, and delivered according to specific drawings and requirements, they offer unparalleled adaptability for wire rod, bar, and tube rolling mills.

Reliability and Compliance You Can Trust

Manufactured under ISO 9001:2015 standards, these roll rings meet stringent quality and consistency metrics. Each piece undergoes precision grinding and surface finishing to achieve exact tolerances and optimal performance. Distributed, exported, and supported by leading suppliers throughout India, they represent a dependable solution for the steel and metal forming industries.

FAQs of Tungsten Carbide Roll Rings:

Q: How are Tungsten Carbide Roll Rings manufactured for improved toughness and precision?

A: These roll rings are produced using Hot and Cold Isostatic Pressing (HIP/CIP) techniques, followed by precision grinding, to achieve high hardness (HRA 78-90), fine dimensional tolerances (0.01 mm), and excellent toughness. Each ring is finished according to required surface specifications, such as polished, mirror, or matte.Q: What are the key benefits of using Tungsten Carbide Roll Rings in rolling mills?

A: Tungsten Carbide Roll Rings provide outstanding wear resistance, excellent corrosion resistance, and extended service lifelasting 5-6 times longer than traditional steel rolls. Their precise dimensions and ability to endure high temperatures up to 900C help maximize mill productivity and reduce maintenance frequency.Q: When should you choose a solid core or a steel-core ring for rolling applications?

A: The choice depends on the applications specific needs. Solid cores are ideal for high-intensity, continuous operations, while rings with steel cores are recommended for heavier rolling or when weight optimization and cost-efficiency are critical, especially in larger diameters.Q: Where are these roll rings primarily used in industrial settings?

A: These rings are widely deployed in wire rod, rebar, seamless tube, and bar rolling mills across India and globally, where durability, precision, and reliability are imperative for high-volume manufacturing processes.Q: What is the process for customizing the dimensions and profiles of these roll rings?

A: Customers provide detailed drawings or specifications, including desired diameter (100450 mm), belt width (up to 150 mm), and shaping (round, oval, or custom). The manufacturer then fabricates the rings accordingly, ensuring precision and compliance with ISO 9001:2015 standards.Q: How does the excellent corrosion resistance of these roll rings benefit mill operations?

A: The superior corrosion resistance of tungsten carbide ensures that the roll rings retain their mechanical properties and surface integrity even in wet or chemically aggressive environments, reducing the risk of unexpected failures and prolonging operational intervals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |