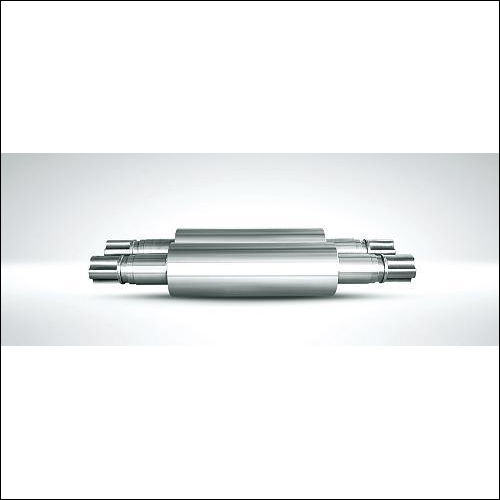

Bainitic Nodular Cast Iron Rolls

Product Details:

- Diameter 150 mm to 1800 mm

- Capacity Customizable as per requirements

- Material Bainitic Nodular Cast Iron

- Dimensions As per drawing or specification

- Technique Centrifugal/Static Casting

- Standard ASTM A897 / EN-GJS Standards

- Belt Width Up to 4500 mm

- Click to View more

Bainitic Nodular Cast Iron Rolls Product Specifications

- Centrifugal/Static Casting

- Bainitic Nodular Cast Iron

- ASTM A897 / EN-GJS Standards

- High toughness, excellent wear resistance, good thermal stability, uniform hardness

- Customizable as per requirements

- As per drawing or specification

- 150 mm to 1800 mm

- Up to 4500 mm

- 200-300 HB

- 340-440 HB

- Machined and ground

- Steel rolling mills, section mills, rail and bar mills

- 300 kg to 12000 kg

- Long, suitable for heavy-duty cycles

- Bainite matrix with spheroidal graphite

- High

- Excellent

- 8 mm to 40 mm

Product Description

Bainitic Nodular Cast Iron Rolls (SGA)

Working as a client centric organization, we are highly acclaimed for presenting an array of Bainitic Nodular Cast Iron Rolls. As compared to other rolls, these are best due to their reliable attributes like their high strength and toughness. Basically, the available range is the result of static casting and centrifugal casting. With the goal to minimize the roll failures, the provided rolls area accessible in different sizes as per the changing demands of our clients. Bainitic Nodular Cast Iron Rolls are obtainable from us at cost effective prices.

Key features:

- Good wearability

- Prevent any kind of breakage

- Optimum size

Chemical Composition

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| SGA I | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | 0.20-1.00 | 3.01-3.50 | 0.50-1.00 |

| SGA II | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | 0.30-1.50 | 3.51-4.50 | 0.50-1.00 |

Prosperities & Application

| Symbol | Hardness | Tensile Strength | Bending Strength | Dimension | Unit N.W |

| SGA I | 55-78 | 350 | 600-800 | 300-1000 | 500-12000 |

| SGA II | 60-80 | 350 | 600-800 |

Exceptional Performance in Rolling Mills

Bainitic Nodular Cast Iron Rolls outperform conventional rolls in both reliability and efficiency, excelling particularly in steel rolling, section mills, rail, and bar mill applications. High impact strength and uniform hardness promote consistent quality output and minimize maintenance stops, making them a preferred choice for heavy-duty industrial cycles.

Advanced Material Composition and Design

The unique bainite matrix reinforced with spheroidal graphite provides remarkable toughness and wear resistance. Core hardness ranges from 200-300 HB, while surface hardness reaches 340-440 HB. This specialized structure, backed by strict adherence to ASTM A897 and EN-GJS standards, ensures reliable performance even under severe operating conditions.

Tailored Solutions and Manufacturing Flexibility

With customizable dimensions, shell depth, and roll weightfrom 300 kg to 12000 kgcustomers receive rolls adapted precisely to their requirements. The latest centrifugal and static casting technologies are employed to deliver consistent quality. Machined and ground finishes ensure optimal integration within existing mill setups, enhanced by world-class distribution and export capabilities from China.

FAQs of Bainitic Nodular Cast Iron Rolls:

Q: How are Bainitic Nodular Cast Iron Rolls manufactured?

A: These rolls are produced through centrifugal or static casting, ensuring uniform microstructure and material density. The process results in a bainite matrix with spheroidal graphite, providing superior wear and impact resistance, and they are finished through precise machining and grinding to meet stringent industry standards.Q: What industries commonly use these cast iron rolls?

A: Bainitic Nodular Cast Iron Rolls are widely implemented in steel rolling mills, section mills, as well as rail and bar mills. Their excellent toughness and thermal fatigue resistance make them suitable for demanding, continuous heavy-duty operations within these industries.Q: When should you select bainitic nodular rolls over other types?

A: These rolls are recommended when operations require a combination of high wear resistance, thermal stability, and impact strength, especially for mills operating under heavy-duty, high-cycle conditions where long service life and reduced downtime are critical.Q: Where are these rolls typically installed during steel processing?

A: They are primarily fitted in rolling mills, including steel, section, rail, and bar mills, where high surface durability and stable hardness over substantial widths and diameters are vital for smooth, uninterrupted processing.Q: What is the core benefit of a bainite matrix in these rolls?

A: The bainite matrix, enhanced with spheroidal graphite, offers significant improvements in toughness, wear resistance, and thermal fatigue resistance. This structure ensures reliable performance and uniform hardness throughout the lifespan of the roll.Q: How can customers customize roll specifications?

A: Clients can tailor the rolls regarding weight (300 kg to 12000 kg), shell depth (8 mm to 40 mm), diameters (150 mm to 1800 mm), and belt width (up to 4500 mm), as well as match any engineering drawing or specification required, to precisely fit unique mill requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |