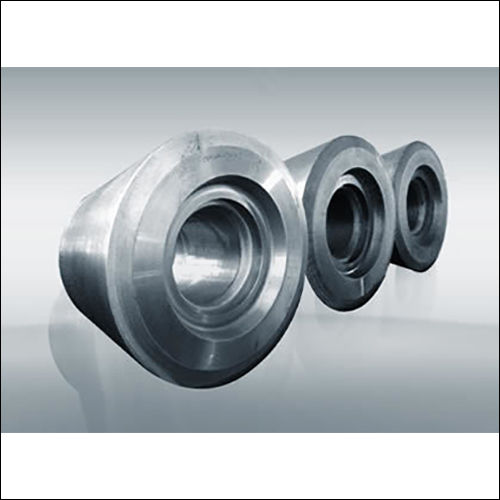

High Chromium Steel Roll

Product Details:

- Diameter 250 mm to 1200 mm

- Capacity Variable depending on rolling application

- Material High Chromium Cast Iron

- Dimensions Customized as per requirement

- Technique Centrifugal Casting

- Standard ASTM A532 / IS 13505

- Belt Width Up to 1000 mm

- Click to View more

High Chromium Steel Roll Product Specifications

- High Chromium Cast Iron

- Variable depending on rolling application

- High wear resistance, Excellent hardness, Extended service life

- ASTM A532 / IS 13505

- Up to 1000 mm

- Centrifugal Casting

- 250 mm to 1200 mm

- Customized as per requirement

- Depending on size, ranges from 300 kg to 3000 kg

- 340 MPa

- Cr: 12-22%, C: 2.0-3.6%, Mo: 0.4-2.0%, Ni: 0.4-2.2%

- Up to 450C

- Rolling mill, Steel plants, Metal forming industry

- Precision ground and heat treated

- HRC 60-65

- 4 J/cm

- Alloy cast iron or ductile iron

- Quenching and tempering

Product Description

High Cr Steel Roll(HCrS)

High Cr Steel Roll is known for having lower carbon content that make it an idealized product range in current industry. Basically, the available range is designed to be used in roughing stands and hot strip mills. A special process of heat treatment is done for making this range strong enough to be used for different applications. High spinning of High Cr Steel Roll increases the speed that specifically creates a centrifugal force so as to push the molten metal into mold.

Key features:

- Good hardness

- Maximum tensile strength

- Superior finish

Chemical Composition

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| HCrS | 1.00-1.80 | 0.40-1.00 | 0.50-1.00 | 8.00-15.00 | 0.50-1.50 | 1.50-4.50 |

Prosperities & Application

| Symbol | Barrel hardness (HS) | Tensile Strength (MPa) | Dimension (MM) | Unit N.W (KGS) | Application |

| HCrS | 70-85 | 450Core | 500-1000 | 1000-25000 | Hot rolling of strip roughing, vertical roll,profile steel universal mill |

Superior Hardness and Wear Resistance

With a hardness range of HRC 60-65 and high chromium content, these rolls ensure outstanding resistance to surface wear, maintaining precision under demanding industrial operations. Their unique composition and manufacturing method guarantee performance and durability in harsh environments, maximizing uptime within rolling and metal forming applications.

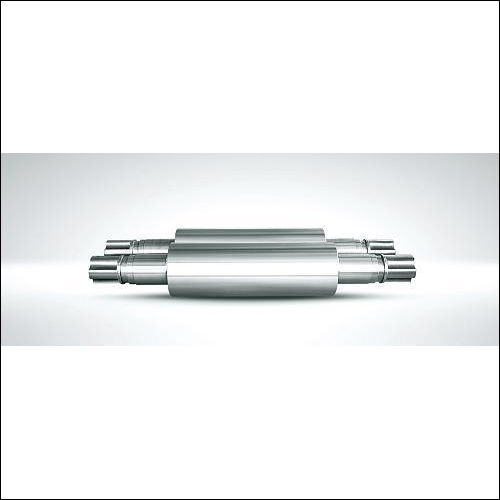

Precision Ground and Heat Treated Surfaces

Each roll undergoes meticulous surface grinding and extensive heat treatment, including quenching and tempering. This precision engineering ensures a consistent, smooth finish that significantly reduces friction and enhances product quality during metal processing.

Customizable Dimensions and Composition

Manufactured to order, High Chromium Steel Rolls can be tailored to match specific operational requirements. Dimensions, diameter, and composition can be precisely adjustedensuring fitment in various machines and processes, and compliance with international standards, including ASTM A532 and IS 13505.

FAQs of High Chromium Steel Roll:

Q: How are High Chromium Steel Rolls manufactured?

A: These rolls are produced using a centrifugal casting technique, which ensures uniform density and strength. After casting, the rolls are precision ground and subjected to quenching and tempering to enhance hardness and wear resistance.Q: What benefits do High Chromium Steel Rolls offer in industrial applications?

A: They provide excellent wear resistance, extended service life, and high hardness, making them ideal for steel plants, rolling mills, and the metal forming industry. Their precision finish supports improved product quality and consistent operational performance.Q: When should High Chromium Steel Rolls be used?

A: These rolls are ideal for intense rolling applications requiring high wear resistance and durability, particularly in steel plants, rolling mills, and metal forming where surface hardness and strength are crucial.Q: Where can these rolls be installed?

A: High Chromium Steel Rolls are suitable for installation in a wide range of rolling mills, steel processing plants, and metal forming operations. They can be utilized wherever the application demands high-performance rolling under significant thermal and mechanical stress.Q: What is the typical chemical composition of these rolls?

A: The rolls are composed primarily of chromium (12-22%), carbon (2.0-3.6%), molybdenum (0.4-2.0%), and nickel (0.4-2.2%), providing the necessary hardness, tensile strength, and impact toughness for industrial usage.Q: How are customized requirements accommodated for these rolls?

A: Manufacturers can adjust the dimensions, core materials, chemical composition, and weight based on the clients applicationranging from 250 mm to 1200 mm in diameter and up to 3000 kg in weight.Q: What is the typical process for using High Chromium Steel Rolls in rolling mills?

A: Rolls are installed in rolling mill stands, where they support and shape metal as it passes through. Their hard, ground surfaces ensure smooth operations, minimal material deformation, and superior finish over long production cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |