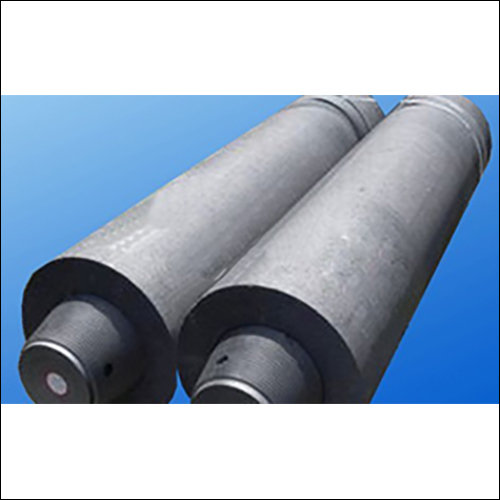

Mandrel bar

Product Details:

- Type Mandrel Bar

- Material Alloy Steel (such as 25CrMo, 30CrMo, Tool Steel, or customized as per requirement)

- Application Seamless Tube and Pipe Manufacturing

- Click to View more

X

Mandrel bar Product Specifications

- Alloy Steel (such as 25CrMo, 30CrMo, Tool Steel, or customized as per requirement)

- Seamless Tube and Pipe Manufacturing

- Mandrel Bar

- 0.15 mm/m

- HRC 36-50 (depending on grade and treatment)

- Nitride Coating / Quenched and Tempered / Induction Hardened

- Ra 0.6 m

- Available upon request

- 900 MPa

- HRC 24-35

- 120 mm - 400 mm

- ASTM, DIN, JIS or as per customer request

- 8000 mm - 17000 mm (customization available)

- High durability for extended use in high-stress environments

Product Description

Mandrel bar is specifically needed for producing different kinds of seamless tubes. This is generally designed for offering general purpose hot steel applications. The steel billet is generally rolled over it with the aid of grooving roll in a stretching manner while reducing the rolling process. Designed with perfection, this range is ideal for determining the shape of inner tube surface. This bar is designed with the perfect combination of advanced machinery system and quality checked materials. we are presenting Mandrel Bar to our clients in numerous specifications.

Key features:

- Robust construction

- Corrosion proof surface

- Optimum length

1. Chrome plating thickness :55~70m

2. Chemical composition (m%)

| Grade | C | Si | Mn | S | P | Cr |

| H13 (4Cr5MoSiV1) | 0.32~0.45 | 0.80~1.20 | 0.2~00.50 | 0.008 | 0.012 | 4.75~5.50 |

| Mo | Ni | V | H | O | ||

| 1.10~1.75 | 0.25 | 0.80~1.20 | 2PPm | 20PPm |

3. Mechanical property

| Size(mm) | Tensile strength Mpa | Yield strength Mpa | Elongation (%) |

| 200 | 1127-1274 | 931 | 8 |

| 200 | 1078-1274 | 882 | 8 |

| Size(mm) | Reduction of area (%) | Impact value | Hardness (HRC) |

| 200 | 25 | 20 | 60-62 |

| 200 | 25 | 20 | 60-62 |

Exceptional Durability for Demanding Operations

Mandrel bars manufactured from robust alloy steels are designed to withstand the high mechanical stress and elevated temperatures of seamless tube and pipe production. Their surface treatments, such as nitriding and induction hardening, optimize resistance against wear and deformation, ensuring dependable and long-lasting performance even under rigorous manufacturing conditions.

Precision Engineering for Reliable Tubing Quality

Each mandrel bar is crafted to strict tolerances, offering exceptional straightness and minimal surface roughness. This high degree of accuracy leads to superior tube uniformity, minimizes production downtime, and enhances overall output efficiency. Mandrel bars are tailored to meet global standards like ASTM, DIN, and JIS, and can be customized upon request for unique process requirements.

FAQs of Mandrel bar:

Q: How are mandrel bars customized to meet specific tube manufacturing requirements?

A: Mandrel bars can be customized in terms of length (from 8000 mm to 17000 mm) and diameter (120 mm to 400 mm). Material composition, surface treatment, hardness, and compliance with standards such as ASTM, DIN, and JIS are also adjustable according to customer specifications to optimize performance for particular manufacturing environments.Q: What is the process for achieving high durability and surface hardness in mandrel bars?

A: High durability and surface hardness are ensured through advanced surface treatments like Nitride Coating, Quenched and Tempered, and Induction Hardening. These processes increase the bars hardness up to HRC 36-50 (surface) and enhance resistance to wear, scoring, and deformation under repeated use in high-stress operations.Q: When should mandrel bars be replaced in seamless tube production?

A: Mandrel bars should be replaced when significant wear, reduced hardness, or deviation in straightness and surface roughness occurs, which could impact the quality of the tubes. Regular inspections based on usage life and environmental stress help determine appropriate replacement intervals for optimal operational efficiency.Q: Where are mandrel bars most commonly applied?

A: Mandrel bars are primarily used in seamless tube and pipe manufacturing facilities, where precise control over tube dimensions is crucial. These bars are supplied globally, often from manufacturers and distributors in China, serving industries that require high-strength, reliable tubing such as oil and gas, construction, and automotive sectors.Q: What benefits do alloy steel mandrel bars offer for industrial tube manufacturing?

A: Alloy steel mandrel bars deliver high tensile strength (900 MPa), excellent wear resistance, and extended operational life. Their precision engineering minimizes tube defects, reduces downtime, and allows for efficient production runseven in challenging, high-stress environments. Customization options further ensure compatibility with diverse manufacturing standards and processes.Q: How does surface roughness (Ra 0.6 m) affect tube quality during manufacturing?

A: Low surface roughness provides a smoother interface, resulting in tubes with better wall uniformity and finish. This minimizes post-processing requirements and reduces internal defects, leading to improved overall product quality and consistency in seamless tube manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |