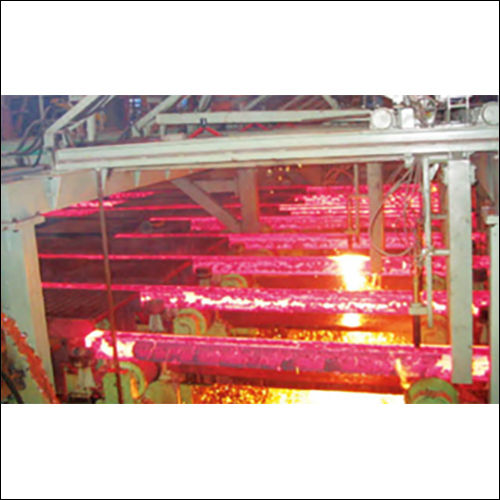

Bar Mill Rolls

Product Details:

- Type Bar Mill Roll

- Material Alloy Steel

- Application Rolling Mills

- Click to View more

X

Bar Mill Rolls Product Specifications

- Rolling Mills

- Alloy Steel

- Bar Mill Roll

- Up to 6 Tons

- 45 to 80 HSD

- Rebar, Wire Rod, and Section Mills

- Wear Resistance, High Strength, Long Service Life

- 150 mm to 600 mm

- Ground or Machined

- 500 mm to 3500 mm

- Induction/Through Hardened

- Ductile Iron or Steel Core

Product Description

To our clients, we are offering a complete solution in the form of Bar Mill Rolls. This array is hugely used for rolling applications and become a premium part of steel industry. The processing of rolling can be done efficiently and widely appreciated for unmatched qualities. The designing of these rolls can be performed by choosing the best range of materials along with advanced machine in adherence to set quality norms. We are presenting these Bar Mill Rolls to our clients at reasonable prices.

Key features:

- Optimum strength

- Highly reliable

- Rust resistant

Precision Performance for Rolling Mills

Bar mill rolls are engineered to deliver optimum performance in rolling mills, particularly those handling rebars, wire rods, and sections. Their precise construction and consistent hardness ensure efficient shaping and high output, supporting demanding operations and minimizing downtime.

Robust Materials & Advanced Heat Treatment

Utilizing alloy steel and advanced heat treatment processes like induction and thorough hardening, these rolls stand out for their exceptional resistance to wear and deformation. The core material, whether ductile iron or steel, offers necessary strength and stability for intense industrial activities.

Versatile Sizing and Finishes

Available in a wide range of diameters and lengths, the rolls can be tailored to specific production setups. The optional ground or machined surface finishes allow for smooth operation and precise product results, crucial for maintaining the quality of finished metal goods.

FAQs of Bar Mill Rolls:

Q: What materials are used in the manufacturing of bar mill rolls?

A: Bar mill rolls are primarily made from high-quality alloy steel, with the core structure consisting of ductile iron or steel, ensuring strength, durability, and resistance to wear during metal forming processes.Q: How are the rolls heat treated to achieve high hardness and wear resistance?

A: The rolls undergo induction or through hardening heat treatment processes, which enhance surface hardness (ranging from 45 to 80 HSD) and impart excellent wear resistance, essential for withstanding rigorous mill operations.Q: Where can these bar mill rolls be applied in the steel industry?

A: Bar mill rolls are widely used in rebar mills, wire rod mills, and section mills for shaping and forming metal bars and rods, supporting various industrial applications and ensuring consistent product quality.Q: What are the benefits of using bar mill rolls with ground or machined surface finishes?

A: Rolls with ground or machined finishes offer improved surface smoothness, which increases rolling efficiency, reduces friction, and helps achieve accurate dimensions on finished products.Q: Who supplies and exports bar mill rolls from China?

A: Renowned distributors, manufacturers, exporters, suppliers, and traders based in China provide bar mill rolls for global markets, meeting the diverse needs of rolling mill operators worldwide.Q: How does the core structure of ductile iron or steel improve the rolls performance?

A: A core made of ductile iron or steel enhances the rolls strength and capacity to withstand high operational stresses, thereby contributing to longer service life and reliable mill performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |