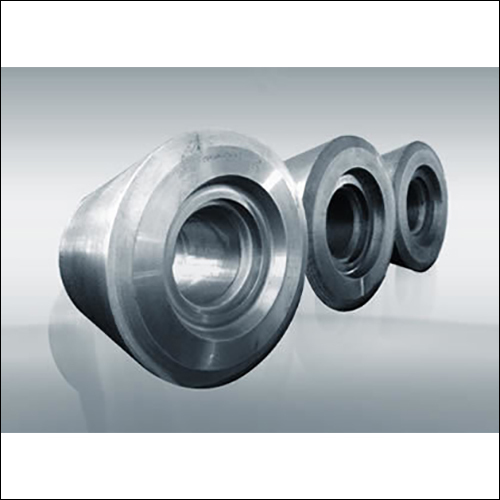

Piercing Rolls

Product Details:

- Diameter 200 mm to 800 mm

- Capacity Up to 50 Tons

- Material Alloy Steel, Forged Steel, Special Steels

- Dimensions Customized as per requirement

- Technique Forged, Heat Treated, CNC Machined

- Standard DIN, ASTM, JIS, Custom

- Belt Width Up to 1000 mm

- Click to View more

Piercing Rolls Product Specifications

- DIN, ASTM, JIS, Custom

- High strength, Precise surface finish, Abrasion resistant

- Forged, Heat Treated, CNC Machined

- Up to 1000 mm

- Customized as per requirement

- 200 mm to 800 mm

- Alloy Steel, Forged Steel, Special Steels

- Up to 50 Tons

- Quenched & Tempered

- ±0.02 mm

- Anti-corrosive treatment available

- Ground and Polished

- Long operational durability

- 50-60 HRC

- Seamless steel tube manufacturing, Hot piercing mills

Product Description

We are regarded as a principal industry who is indulged in the market for offering Piercing Rolls. It is used for hot forming process required for enlarging the length of seamless tube and pipe. Mainly, compressive forces are applied to a cylinder for creating an internal stresses at the centre. We are designing this range by selecting the premium grade of materials and most advanced tooling system that works in combination as per market trends. Our clients are offering these Piercing Rolls to our clients at best industrial rates.

Key features:

- Simple usage

- High compatibility

- Smooth working

Material: 45,55,40Cr,60CrMnMo,50Mn and so on

Hardness :HB240~280(as per required )

Metallurgical structure :Granular bainite

Manufacturing procedure :Forging ,casting

Production capacity :5000t/year

Superior Hardness and Durability

With a hardness rating of 50-60 HRC and heat treatment by quenching and tempering, these piercing rolls are engineered to withstand the rigors of continuous hot piercing in steel tube mills. Their long operational durability ensures consistent performance, even under heavy loads up to 50 tons, minimizing downtime and maintenance costs.

Unmatched Precision and Finish

Every piercing roll is meticulously ground and polished, achieving a precise surface finish and tight tolerance of 0.02 mm. CNC machining guarantees consistency, while anti-corrosive coatings further extend lifespan. Choose from custom dimensions and belt widths up to 1000 mm to match your unique manufacturing requirements.

Global Standards and Versatility

Manufactured in China and meeting international standards including DIN, ASTM, and JIS, these rolls are suitable for various tube mills worldwide. Available for distributors, exporters, manufacturers, suppliers, and traders, they cater to a broad range of industrial needs, ensuring reliability and adaptability through customization.

FAQs of Piercing Rolls:

Q: How are the piercing rolls manufactured to ensure high precision and durability?

A: Piercing rolls are forged from alloy, forged, or special steels, then heat treated by quenching and tempering to achieve a hardness of 50-60 HRC. Advanced CNC machining delivers precise dimensions and superior ground and polished surface finishes, ensuring durability even under heavy operational loads.Q: What applications are piercing rolls suitable for?

A: These rolls are designed primarily for seamless steel tube manufacturing in hot piercing mills. They can be used wherever high strength, precise surface finish, and abrasion resistance are required, supporting diverse tube production processes globally.Q: When should anti-corrosive coatings be used on piercing rolls?

A: Anti-corrosive coatings are recommended for environments where rolls are exposed to humidity, chemicals, or frequent cleaning. This treatment significantly extends service life, particularly in outdoor or high-moisture tube mill conditions.Q: Where can piercing rolls be sourced and customized?

A: Piercing rolls are available through various channels, including distributors, exporters, manufacturers, suppliers, and traders, primarily based in China. Customization options for dimensions, belt width, and materials can be specified to meet individual production requirements and standards.Q: What is the standard tolerance and how does it benefit manufacturing?

A: A precise tolerance of 0.02 mm ensures that each roll fits seamlessly into the production line, maintaining consistent tube wall thickness and improving overall product quality. This accuracy reduces material waste and boosts manufacturing efficiency.Q: What benefits do heat-treated and CNC machined rolls offer over conventional options?

A: Heat treatment and CNC machining provide enhanced strength, fatigue resistance, and precise sizing. These features lead to extended service life, lower maintenance needs, and optimal performance in demanding tube manufacturing operations.Q: How does using alloy or special steel materials impact the service life of piercing rolls?

A: Alloy and special steel materials offer superior strength and resistance to abrasion and deformation, resulting in longer operational durability. This makes the rolls ideal for handling high production volumes and reducing the frequency of replacements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |