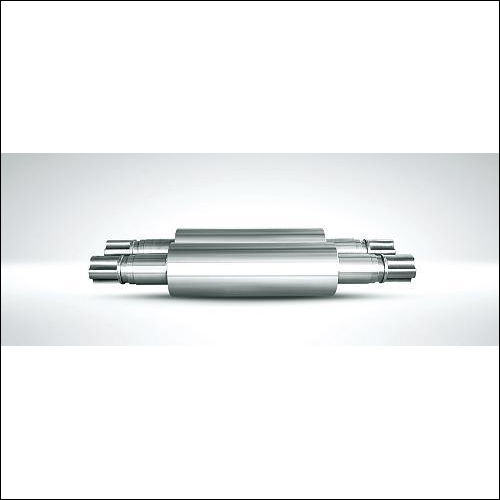

Adamite Rolls

Product Details:

- Diameter 150 mm to 1200 mm

- Capacity Suitable for heavy-duty rolling operations

- Material Alloyed steel and adamite iron

- Dimensions As per client specifications

- Technique Centrifugal casting and heat treatment

- Standard ASTM/BS/IS standards

- Belt Width Customizable as per requirement

- Click to View more

Adamite Rolls Product Specifications

- Customizable as per requirement

- ASTM/BS/IS standards

- 150 mm to 1200 mm

- High wear resistance, excellent toughness, deep hardness

- As per client specifications

- Suitable for heavy-duty rolling operations

- Centrifugal casting and heat treatment

- Alloyed steel and adamite iron

- Up to 7000 kg

- Square, grooved, and customized

- Long-lasting with minimal wear

- High thermal stability for continuous operation

- Adamite Rolls (Cast/ Forged)

- 35-55 HRC

- Steel rolling mills, section mills, bar mills, wire rod mills

- 25-35 HRC

- Available as per specific mill and process requirements

- Smooth, machined with high precision

Product Description

Adamite Rolls (AD)

Our provided Adamite Rolls are mainly composed of pearlite along with cementite. As compared to others, these rolls are much stronger and harder, hence used for various applications. Integrated with outstanding features, the available rolls have the inner hardness quite enough for milling and rolling process. Our proposed range is especially available as hyper-eutectoid steel rolls made up of nickel, chromium and molybdenum. Designing of these Adamite Rolls is done while procuring the best quality of materials with most advanced machine as per industrial quality norms.

Key features:

- High strength

- Superior finish

- Long-lasting working

Chemical Composition

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| AD140 | 1.30-1.50 | 0.30-0.60 | 0.70-1.10 | 0.80-1.20 | 0.50-1.10 | 0.20-0.60 |

| AD160 | 1.50-1.70 | 0.30-0.60 | 0.80-1.30 | 0.80-2.00 | 0.20 | 0.20-0.60 |

| AD180-AD200 | 1.70-2.10 | 0.30-0.80 | 0.60-1.20 | 0.80-3.50 | 0.50-2.50 | 0.20-0.80 |

| ADGT | 1.40-1.60 | 0.30-0.80 | 0.70-1.50 | 1.00-2.00 | 1.00-3.00 | 0.40-0.80 |

Prosperities&Application

| Symbol | Hardness | Tensile Strength | Elongation | Dimension | Unit N.W | Application |

| AD140 | 35-50 | 500-800 | 1.0 | 400-1400 | 1000- 40000 | Rolls for blooming mills |

| AD160 | 40-60 | 500-800 | 1.0 | |||

| | ||||||

| AD180- | 45-65 | 450-700 | 0.5 | Rolls for hot strip mills | ||

| | ||||||

| ADGT | 50-60 | 690-850 | 0.5 | Rolls for blooming mills |

High Performance for Steel Mills

Adamite Rolls deliver exceptional durability and reliability for steel rolling mills, section mills, bar mills, and wire rod mills. Their engineered material composition ensures they tolerate the intense pressures and temperatures encountered during continuous, heavy-duty operations. These rolls are manufactured to meet global industry standards, making them a trusted solution for various mill configurations and requirements.

Customized to Meet Your Needs

Our Adamite Rolls are fully customizable in terms of diameter, width, edge type, and machining tolerances. Whether you require square, grooved, or specially tailored edges, we work closely with clients to develop rolls that meet specific mill and process requirements. This versatility ensures seamless integration and optimal performance across varied production lines.

FAQs of Adamite Rolls:

Q: How do Adamite Rolls enhance the performance of steel rolling mills?

A: Adamite Rolls are designed to deliver high wear resistance, deep hardness, and excellent toughness, which collectively improve productivity and extend the service life of the equipment in steel rolling mills. Their high thermal stability allows for continuous operation without significant degradation.Q: What is the manufacturing process for Adamite Rolls?

A: Adamite Rolls are produced using centrifugal casting methods, followed by precise heat treatment procedures. This process ensures uniform material distribution, optimal hardness, and strong structural integrity, resulting in rolls that can withstand substantial mechanical and thermal loads.Q: When are Adamite Rolls typically used in production cycles?

A: Adamite Rolls are implemented throughout continuous and heavy-duty manufacturing cycles in rolling mills, particularly where extended operation and minimal downtime are crucial. They are suitable for primary, intermediate, and finishing stands depending on the specific mill setup and application.Q: Where are Adamite Rolls most commonly installed?

A: These rolls are predominantly installed in steel rolling mills, section mills, bar mills, and wire rod mills. Their versatility in edge design and dimensional customization also allows them to fit a wide range of rolling and forming equipment in different regions and plants.Q: What benefits do Adamite Rolls offer compared to other roll materials?

A: Adamite Rolls combine the advantages of alloyed steel strength and cast iron toughness, providing deeper hardness and superior resistance to surface and core wear. This results in less frequent roll replacement, reduced maintenance costs, and improved operational efficiency.Q: How can the customization of Adamite Rolls be specified?

A: Clients can specify requirements such as roll diameter, length, edge type (including square and grooved), belt width, and finish. Rolls are manufactured to align with ASTM, BS, or IS standards and can be tailored for unique process demands and machinery dimensions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |