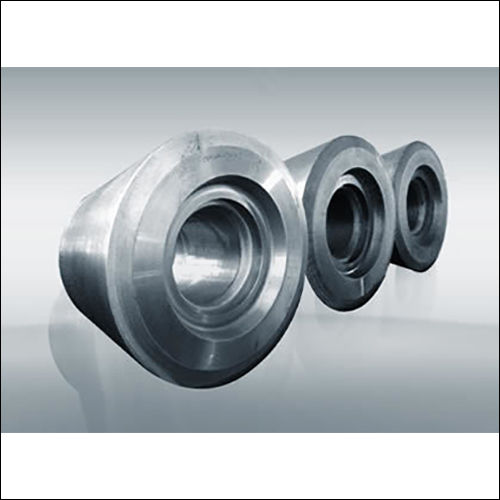

Rolled Steel Bar Rings

Product Details:

- Diameter 50 mm to 1000 mm or customized

- Capacity Up to 5 Tons

- Material Rolled Steel (Mild Steel, Carbon Steel, Alloy Steel)

- Dimensions As per drawing or requirement

- Technique Hot Rolled/Cold Rolled

- Standard IS 2062, ASTM A36, EN8, or as specified by client

- Belt Width Customizable as per application

- Click to View more

Rolled Steel Bar Rings Product Specifications

- Rolled Steel (Mild Steel, Carbon Steel, Alloy Steel)

- High strength, Corrosion resistance, Durable finish, Precise dimensions

- 50 mm to 1000 mm or customized

- IS 2062, ASTM A36, EN8, or as specified by client

- Up to 5 Tons

- Hot Rolled/Cold Rolled

- Customizable as per application

- As per drawing or requirement

- 0.05 mm or as per specification

- Automobile, Engineering, Industrial Machinery, Construction

- As per standard export packing or customer requirement

- For making bearing rings, gear blanks, flanges, etc.

- EN8, C45, C55, or customer specified

- Smooth and burr-free edges

- 150-250 HB

- Round

- Bright, Black, or as required

- Ultrasonic Tested, Chemical and Physical Analysis Provided

Product Description

Rolled Steel Bar Rings are the easiest way to be used along with flanges for offering reliable performance. Along with this, the available range is designed to be used with collars and strengtheners. The rings have the capability to withstand the adverse conditions and featured with quick release mechanism. To meet the variegated needs of our clients, the rings are developed while choosing the premium grade of materials that are procured from reliable vendors of the market. Clients can purchase these Rolled Steel Bar Rings in different specifications at reasonable prices.

Key features:

- Corrosion proof

- Reliable performance

- Optimum strength

YGR series of roll rings

Prosperties:

| Grade | Chemical | Mechanical properties | Physical properties | |||||

| Co+Ni% | WC% | Hardness | Transverse Bending strength | compressive strength | Young's modulus of elasticity | Density | Thermal conductivity | |

| YGR20 | 12 | 88 | 84.0 | 2300 | 3400 | 550 | 14.0-14.3 | 0.21 |

| YGR25 | 15 | 85 | 83.0 | 2570 | 3200 | 500 | 13.4-13.9 | 0.19 |

| YGR30 | 18 | 82 | 82.0 | 2570 | 3100 | 480 | 13.3-13.9 | 0.18 |

| YGR40 | 20 | 80 | 82.0 | 2570 | 3100 | 480 | 13.3-13.9 | 0.18 |

| YGR45 | 20 | 80 | 80.5 | 2250 | 3000 | 480 | 13.4-13.9 | 0.18 |

| YGR55 | 25 | 75 | 79.0 | 2400 | 2800 | 420 | 12.9-13.4 | 0.17 |

| YGR60 | 30 | 70 | 78.5 | 2200 | 2600 | 300 | 12.6-13.1 | 0.16 |

Precision Engineering, Superior Performance

Our Rolled Steel Bar Rings are manufactured using advanced hot or cold rolling techniques, yielding precise shapes and dimensions tailored to client requirements. Stringent quality controls, including ultrasonic tests and material analysis, guarantee reliable performance in demanding applications such as bearing rings, gear blanks, and flanges, offering both standard and customizable solutions.

Versatility across Industries

These steel bar rings are designed for diverse sectors ranging from automotive to construction. They are available in multiple surface finishes and steel grades, complying with international standards like IS 2062, ASTM A36, and EN8. High strength, corrosion resistance, and a durable finish make them a trusted choice for industrial operations worldwide.

FAQs of Rolled Steel Bar Rings:

Q: How are the Rolled Steel Bar Rings manufactured and tested for quality?

A: Our Rolled Steel Bar Rings are produced using either hot rolled or cold rolled techniques, depending on the application and client requirements. Each ring undergoes ultrasonic testing and both chemical and physical analysis to verify structural integrity and material specifications, ensuring high performance and safety.Q: What are the primary applications of these steel bar rings?

A: These rings are commonly used in industries such as automotive, engineering, machinery, and construction. Typical applications include manufacturing bearing rings, gear blanks, and flanges, thanks to their precise dimensions, robust strength, and durable finish.Q: When should I choose a customized specification for my steel ring order?

A: Customized specifications are ideal when you have distinct dimensional, tolerance, or material requirements for unique machinery, equipment, or structural use. Our factory supports customization in diameter, grade, surface finish, and tolerance to match individual project needs.Q: Where can these Rolled Steel Bar Rings be supplied?

A: We operate as a manufacturer, exporter, distributor, supplier, and trader, capable of delivering these rings globally, including to regions across China and beyond. Export standard packaging and customer-specific requirements ensure secure and efficient shipment.Q: What benefits do these rings offer compared to conventional alternatives?

A: Our rings provide high strength, corrosion resistance, and exceptional durabilityall with precision dimensions and smooth, burr-free edges. This leads to increased equipment lifespan and reliable performance in critical applications.Q: How is the packing and delivery managed for international orders?

A: Packing adheres to standard export protocols or can be tailored to customer instructions. Our logistics team ensures products are adequately protected and shipped efficiently, meeting both safety standards and timelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

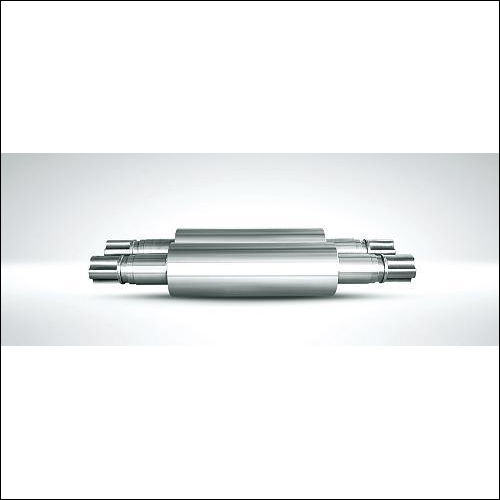

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |