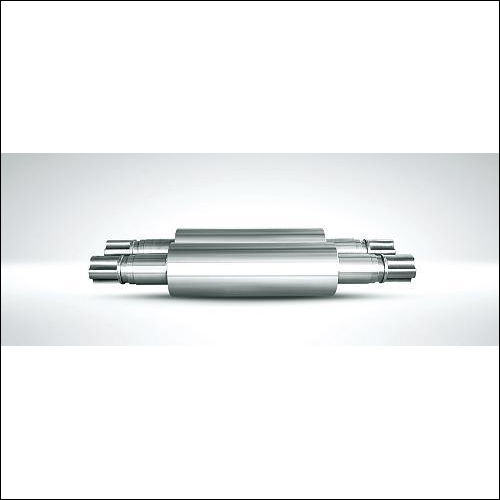

Clear Chilled Rolls

Product Details:

- Diameter 300 mm to 1500 mm

- Capacity Customizable as per requirement

- Material Chilled Cast Iron

- Dimensions As per customer drawing or specification

- Technique Centrifugal Casting

- Standard DIN EN ISO 9453

- Belt Width 150 mm to 2000 mm

- Click to View more

Clear Chilled Rolls Product Specifications

- Customizable as per requirement

- High Surface Hardness, Uniform Structure, Superior Finish

- Centrifugal Casting

- As per customer drawing or specification

- DIN EN ISO 9453

- 150 mm to 2000 mm

- Chilled Cast Iron

- 300 mm to 1500 mm

- Clear, Smooth, Machined

- Rolling Mills, Paper Mills, Textile Mills

- Dynamic Balancing Available

- Wooden Box or as per customer specification

- 40 - 75 Shore C

- Solid or Hollow as per requirement

- upto 7000 mm

- 350 - 500 MPa

- Annealed & Normalized

- 1 Piece

Product Description

Clear Chilled Rolls (CC)

Clear Chilled Rolls, as the name suggests are definite range used for different automatic and semi automatic rolling plant. These are chilled in nature and made with the process of composition. Depending on the requirements, the chill depth can be decided. Also, the hardness of such rolls also ranges as per needs of the process. The available rolls are one of their kinds that do not compromise of graphite in the matrix. Clients can buy these Clear Chilled Rolls at market leading rates.

Key features:

- Durable finish

- Good thermal property

- Easy to use

Chemical Composition

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| CC | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.20-0.60 | 0.50-1.00 | 0.20-0.60 |

| CC | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.30-1.20 | 1.01-2.00 | 0.20-0.60 |

| CC | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.50-1.50 | 2.01-3.00 | 0.20-0.60 |

| CC | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.50-1.70 | 3.01-4.50 | 0.20-0.60 |

| Symbol | Hardness | Tensile Strength | Bending Strength | Dimension | Unit N.W | Application |

| CC | 60-70 | 150 | 300-400 | 300-800 | 300-7000 | Rolls for finishing stands of small section mills, bar and wire mills,hot narrow strip mills |

| CC | 60-80 | 150 | 300-400 | |||

| CC | 62-75 | 350 | 500-700 | |||

| CC | 70-85 | 350 | 500-700 |

High-Precision Engineering for Advanced Industrial Use

Clear Chilled Rolls are crafted through centrifugal casting, resulting in robust, uniform structures designed to excel in demanding industrial settings. With customizable capacities and dimensions, each roll is tailored to meet diverse operational needs in rolling, paper, and textile mills, combining superior surface finish with reliable performance.

Optimal Surface Hardness and Finish

These rolls boast a distinct hardness range of 40 - 75 Shore C and a meticulously machined surface, ensuring excellent wear resistance and smooth operation. The clear and consistent finish enhances process efficiency while maintaining product quality in high-output settings.

Strict Quality Standards and Flexible Packaging

Manufactured under the rigorous DIN EN ISO 9453 standard, Clear Chilled Rolls undergo dynamic balancing and heat treatments such as annealing and normalization. Packaging is tailored according to customer requirements, ensuring safe transit and storage of every customized roll.

FAQs of Clear Chilled Rolls:

Q: How are Clear Chilled Rolls manufactured to achieve their superior surface hardness?

A: Clear Chilled Rolls are produced using centrifugal casting, followed by specific heat treatments like annealing and normalization. This process ensures a uniform structure and high surface hardness ranging from 40 to 75 Shore C, making them exceptionally durable and resistant to wear.Q: What applications are Clear Chilled Rolls suitable for?

A: These rolls are designed for use in rolling mills, paper mills, and textile mills. Their robust construction and smooth, clear finish make them ideal for demanding industrial processes that require consistent and precise results.Q: When should dynamic balancing be chosen for these rolls?

A: Dynamic balancing is recommended during manufacturing if the rolls will rotate at high speeds or be used in applications where operational stability is crucial. It minimizes vibrations and extends the life of both the roll and the machinery.Q: Where can Clear Chilled Rolls be installed, and are installation services available?

A: Clear Chilled Rolls can be installed in any mill setting that matches the specified application. While manufacturers or suppliers often provide technical assistance and guidance, customers should consult their distributor or exporter in China for detailed installation services.Q: What is the process for customizing dimensions and core structures of the rolls?

A: Customers can provide specific drawings or dimension requirements. The manufacturer tailors the rolls length, diameter, core structure (solid or hollow), and belt width as per customer specifications, ensuring an optimal fit for each unique industrial setup.Q: How does the product benefit industrial operations?

A: With features like high surface hardness, superior finish, and customizable design, Clear Chilled Rolls enhance operational efficiency, reduce downtime, and help maintain product quality across various manufacturing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |