High Boron Steel Rolls

Product Details:

- Capacity up to 6000 MT per annum

- Diameter 150 mm to 1400 mm

- Material High Boron Alloy Steel (Fe-B alloy)

- Dimensions Customized as per clients requirements

- Technique Static Casting, Centrifugal Casting, Machining, Surface Hardening

- Standard IS: 5517, ASTM A388/A1035, JIS G 5613

- Belt Width 100 mm to 1200 mm

- Click to View more

High Boron Steel Rolls Product Specifications

- High Boron Alloy Steel (Fe-B alloy)

- up to 6000 MT per annum

- High wear resistance, longer service life, excellent surface finish

- IS: 5517, ASTM A388/A1035, JIS G 5613

- Static Casting, Centrifugal Casting, Machining, Surface Hardening

- Customized as per clients requirements

- 100 mm to 1200 mm

- 150 mm to 1400 mm

Product Description

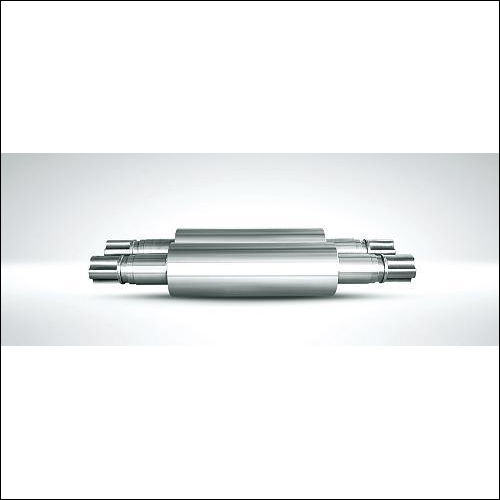

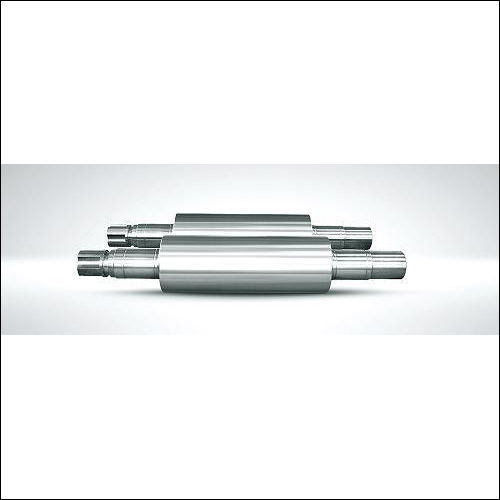

High Boron Steel Rolls (HBSR)

Due to the continuous efforts of our skilled professionals, we are capable of presenting best in class range of High Boron Steel Rolls. Our offered rolls are the result of heat treatment that includes normal double annealing method followed by tempering cycle. This in turn makes the toughness of this range much better. Thus, our offered rolls are certainly used in metal forming process in which there is a presence of a stock of metal passed through of steel rolls. High Boron Steel Rolls are easily accessible to our clients at leading market price.

Key features:

- Reliable performance

- Enhanced working life

- Superior finish

Chemical Composition

| Symbol | C | Si | Mn | W | V | Cr | Ni | Mo | Nb | B |

| HSS | 1.50-2.20 | 0.30-1.00 | 0.40-1.20 | 0.00-8.00 | 2.00-9.00 | 3.00-8.00 | 0.00-1.50 | 2.00-8.00 | 0.00-2.00 |

|

| S-HSS | 0.60-1.20 | 0.80-1.50 | 0.50-1.00 | 0.00-3.00 | 0.40-3.00 | 3.00-9.00 | 0.20-1.20 | 2.00-5.00 | 0.00-2.00 |

|

| B-HSS | 1.00-2.00 | 0.30-1.00 | 0.40-1.20 | 0.00-3.00 | 0.40-3.00 | 7.00-12.00 | 0.20-1.20 | 2.00-5.00 | 0.00-2.00 | 0.10-1.00 |

Prosperities & Application

| Symbol | Barrel hardness (HS) | Neck hardness (HS) | Dimension (MM) | Unit N.W (KGS) | Application |

| HSS | 75-95 | 30-45 | 400-700 | 800- 15000 | Finishing work rolls for hot strip mills and bar mills; |

| S-HSS | 75-98 | 30-45 |

|

| Roughing work rolls for hot strip mills; work rolls and intermediate rolls for cold strip mills

|

| B-HSS | 75-85 | 30-45 |

|

|

Superior Wear Resistance and Extended Lifespan

Thanks to a high boron content and fine pearlitic with boride phase microstructure, these steel rolls offer remarkable resistance to wear and long operational life. The robust surface, treated by induction hardening and shot blasting, ensures consistent performance in demanding rolling environments, reducing downtime and replacement frequency.

Precision Engineering for Customized Applications

Each roll is meticulously crafted with customizable dimensions and weights, providing precise solutions for diverse applications in hot and cold rolling as well as section mills. Tight manufacturing tolerances of 0.01 mm and advanced testing guarantee the reliability, accuracy, and tailored performance required by clients worldwide.

Uncompromising Quality and International Standards

High Boron Steel Rolls are manufactured under strict quality protocols, including ultrasonic and magnetic particle inspections, aligning with global standards such as IS: 5517, ASTM A388/A1035, and JIS G 5613. The manufacturing process adopts both static and centrifugal casting, ensuring superior strength and uniformity throughout every product.

FAQs of High Boron Steel Rolls:

Q: How are High Boron Steel Rolls typically used in the industry?

A: High Boron Steel Rolls are predominantly utilized in hot and cold rolling mills, as well as section mills. Their high wear resistance and surface hardness make them especially suitable for heavy-duty industrial applications requiring a durable, long-lasting roll.Q: What is the manufacturing process involved for these rolls?

A: The rolls are produced via static or centrifugal casting followed by precision machining and surface hardening. Surfaces are treated with induction hardening and shot blasting, and every roll undergoes stringent quality checks including ultrasonic and magnetic particle inspection to ensure flawless performance.Q: When should I consider using dense chilled iron/steel cores in my rolls?

A: Dense chilled iron or steel cores are recommended when higher core strength or specific mechanical properties are required for demanding rolling operations. These cores are available upon request to further enhance the rolls structural integrity.Q: Where are these rolls supplied and exported from?

A: These High Boron Steel Rolls are manufactured, supplied, and exported from China. They cater to a global clientele, including manufacturers, distributors, exporters, suppliers, and traders across various countries.Q: What benefits do these rolls offer compared to conventional materials?

A: With a unique high-boron composition and a microstructure optimized for pearlitic and boride phases, these rolls provide superior wear resistance, longer service life, minimal maintenance, and an excellent surface finish, outclassing conventional rolls in both longevity and performance.Q: How is product quality ensured during production?

A: Each roll undergoes comprehensive ultrasonic and magnetic particle inspections to detect subsurface and surface irregularities. Manufacturing follows strict tolerances (0.01 mm) and aligns with major international standards, ensuring consistent high-quality output.Q: What are the packaging and shipping options for these rolls?

A: Rolls are securely packaged in wooden cases or palletized as per customer requirements. This method ensures protection against damage during transport and easy handling at the destination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |