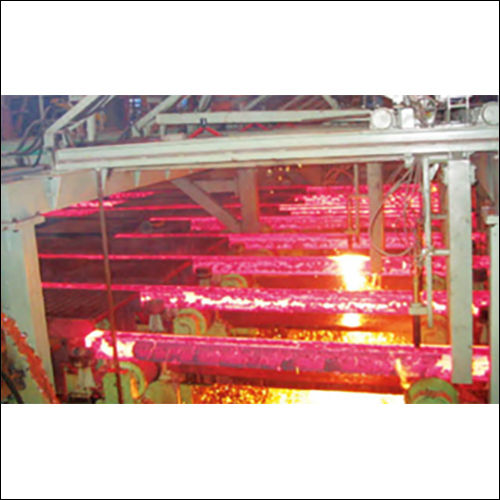

Ladle Covering System

Product Details:

- Type Ladle Covering System

- Material Mild Steel

- Application Steel Plant / Foundry

- Click to View more

X

Ladle Covering System Product Specifications

- Steel Plant / Foundry

- Mild Steel

- Ladle Covering System

- Horizontal/Vertical movement as required

- Automatic/Semi-Automatic

- Can be customized for different ladle types

- Paint Coated / Anti Corrosive Treatment

- Efficient covering and uncovering of steel ladles to reduce heat loss and prevent oxidation

- Motorized or Manual Operation

- Designed as per ladle size and requirement

- PLC based control (optional)

- Robust construction for long operational life

- High-grade refractory lining for heat retention

Product Description

As a customer focused organization, we are proudly presenting an outstanding range of Ladle Covering System. It is a kind of vessel required for transporting and pouring molten metal with utmost ease. Basically, this ideally resemble the kitchen ladle and has the ability to hold large capacity. Thus, the offered range is widely used in numerous steel mills. In compliance with industrial laid norms, the manufacturing of this Ladle Covering System can be performed while choosing quality grade materials and updated machine.

Key features:

- Superior strength

- Simple to use

- Durable performance

Efficient Heat Retention and Protection

By employing advanced refractory lining, the Ladle Covering System effectively retains heat, significantly reducing thermal losses and minimizing the risk of oxidation. This feature is especially valuable for maintaining the quality of molten steel during transfer and storage, leading to improved yield and operational efficiency in steel manufacturing environments.

Flexible Operation and Customization

The system offers both manual and motorized mechanisms, with options for automatic or semi-automatic modes and PLC-based controls, adapting seamlessly to diverse ladle types and process requirements. Horizontal or vertical movement further enhances usability while customization options allow the system to fit various ladle specifications found in steel plants and foundries.

FAQs of Ladle Covering System:

Q: How does the Ladle Covering System help reduce heat loss during ladle operations?

A: The system uses high-grade refractory insulation within the lid, which retains heat inside the ladle and minimizes heat dissipation. This efficient thermal management helps maintain optimal temperatures for molten steel, ensuring process stability and energy savings.Q: What operation modes are available for the Ladle Covering System?

A: The Ladle Covering System can be operated manually or through motorized mechanisms. Users may choose between automatic or semi-automatic modes, with optional PLC-based control for enhanced automation and process integration.Q: When should I use a Ladle Covering System in my steel plant or foundry?

A: The system is best used during ladle charging, transfer, or holding stages when it is essential to conserve heat and prevent oxidation of molten steel. Implementing the cover at these crucial moments safeguards material quality and reduces overall energy consumption.Q: Where can the Ladle Covering System be installed?

A: It can be set up in any section of a steel plant or foundry where ladle operations occur, including ladle transfer stations, furnace areas, or holding bays. Its adaptable design allows for installation across various plant layouts.Q: What is the typical process for operating the cover over a ladle?

A: Operators engage the system using either manual controls or motorized features. Depending on the setup, the cover moves horizontally or vertically to securely shield the ladle. Automated options using PLC further streamline and monitor the covering process for consistent results.Q: How can customizing the system benefit my operations?

A: Customization ensures compatibility with different ladle shapes and sizes, optimizing protection and performance. Tailoring the system to your facilitys specific needs helps achieve maximum efficiency in covering and uncovering operations, facilitating smoother workflows.Q: What are the main advantages of using the Ladle Covering System?

A: Key benefits include improved heat retention, reduced oxidation, operational flexibility, extended durability due to robust mild steel construction, and minimized maintenance with anti-corrosive finishes. These advantages collectively support better product quality and cost savings for steel producers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |