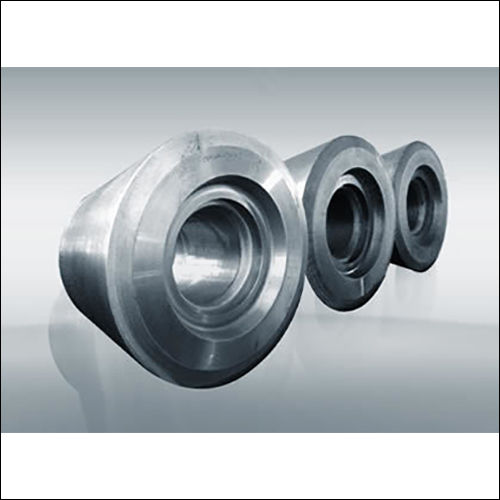

Roll Shaft Sleeve

Product Details:

- Capacity Suitable for heavy-duty and continuous operations

- Diameter Customizable from 50 mm to 300 mm

- Material Alloy Steel / Mild Steel / Stainless Steel

- Dimensions Custom as per client requirements

- Technique CNC machining & precision grinding

- Standard IS & DIN standard

- Belt Width Varies as per application

- Click to View more

Roll Shaft Sleeve Product Specifications

- Custom as per client requirements

- Suitable for heavy-duty and continuous operations

- High wear resistance, precision fit

- IS & DIN standard

- CNC machining & precision grinding

- Varies as per application

- Customizable from 50 mm to 300 mm

- Alloy Steel / Mild Steel / Stainless Steel

- Cylindrical / Customized

- 0.01 mm

- Depends on dimension and material

- Silver/Grey (metallic finish)

- 42-60 HRC (as per material selection)

- Conveyor Rollers, Printing Rollers, Industrial Shafts

- Polished, Anti-corrosive Coating

- Easy mounting with locking arrangement

Product Description

Matching with the wide requirements of our clients, we are presenting the best in class range of Roll Shaft Sleeve. This range is present as a hollow metal tube, placed over haft in order to provide protection at the time of packing. Our proposed range is designed with the selection of quality tested materials that are procured from trustworthy vendors in the market. In order to ensure that quality range is delivered at clients end, Roll Shaft Sleeve is inspected on different quality constraints.

Key features:

- Smooth finishing

- High strength

- Anti corrosive

Chemical Composition

| Name | C | Si | Mn | Cr | Ni | Mo |

| SGP | 2.90/3.60 | 1.00/2.20 | 0.40/1.00 | 0.20/1.20 | 1.50/3.00 | 0.20/0.80 |

| SGA | 2.90/3.60 | 1.00/2.20 | 0.20/0.80 | 0.20/1.50 | 3.00/4.50 | 0.50/1.00 |

| Adamite | 1.50/2.10 | 0.30/0.80 | 0.60/1.30 | 0.80/3.50 | 0.50/2.50 | 0.20/0.80 |

| GT Adamite | 1.40/1.60 | 0.30/0.80 | 0.70/1.50 | 1.00/2.00 | 1.00/3.00 | 0.40/0.80 |

| GS | 1.60/2.20 | 1.20/2.00 | 0.50/1.50 | 1.00/3.00 | 1.00/3.00 | 0.40/0.80 |

Prosperities & Application

| Name | Hardness (HS) | Tensile Strength | Dimension (MM) | Unit N.W (KGS) | Application |

| SGP | 55-65 | 450 | 400-1700 | 400-10000 | Sleeve for universal mill, |

| SGA | 60-70 | 450 | |||

| Adamite | 50-60 | 600 | |||

| GT Adamite | 55-65 | 700 | |||

| GS | 55-75 | 700 |

Precision Engineering for Industrial Applications

Tailored to match complex operational demands, these Roll Shaft Sleeves deliver superior wear resistance and precise fit for industrial rollers and shafts. Manufactured using state-of-the-art CNC machining and grinding, each sleeve provides reliability, longevity, and outstanding surface finish. The customizable options make them versatile for a broad range of industries, from conveyors to high-performance printing machinery.

Customizable Dimensions and Superior Material Options

Choose from alloy steel, mild steel, or stainless steel to suit your specific application needs. With customizable diameters (50 mm to 300 mm) and variable lengths, our sleeves accommodate a range of equipment designs. Manufactured to IS & DIN standards, they assure compatibility, robustness, and exacting tolerances, contributing to seamless machine integration.

FAQs of Roll Shaft Sleeve:

Q: How is the Roll Shaft Sleeve installed?

A: Installation is simplified with the provided locking arrangement, allowing for secure and quick mounting on conveyor rollers, printing rollers, or industrial shafts. Each sleeve is designed for a precision fit to avoid operational issues.Q: What is the advantage of the anti-corrosive coating on the sleeve?

A: The anti-corrosive coating protects the sleeve from rust and environmental degradation, extending its service life even in moist or chemically aggressive environments, and reducing maintenance frequency.Q: When should I use a customized diameter or shape for the Roll Shaft Sleeve?

A: Customization is recommended when your equipment requires non-standard dimensions, ensuring optimal load distribution, wear properties, and alignment for maximum operational efficiency.Q: Where can these Roll Shaft Sleeves be applied?

A: They are ideal for use in conveyor systems, printing machinery, and a wide variety of industrial shaft applications requiring high wear resistance and precision alignment.Q: What is the manufacturing process used for these sleeves?

A: The sleeves are produced by advanced CNC machining followed by precision grinding. This process ensures tight tolerances (0.01 mm), smooth surface finishes, and consistent hardness as per the selected material.Q: How does the choice of material impact sleeve performance?

A: Material selection (alloy steel, mild steel, or stainless steel) determines hardness, wear resistance, and corrosion resistance, allowing adaptation for light to heavy-duty, as well as corrosive, environments.Q: What benefits do these sleeves provide in continuous industrial operations?

A: They ensure smoother operation, improved durability, and decreased downtime due to their robust construction, high precision, and easy maintenancecrucial for heavy and uninterrupted production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |