Billet Auto Cutter

Product Details:

- Type Automatic Billet Cutter

- Material Heavy Duty Steel

- Application Industrial Metal Cutting

- Click to View more

X

Billet Auto Cutter Product Specifications

- Heavy Duty Steel

- Industrial Metal Cutting

- Automatic Billet Cutter

- Painted/Anti-corrosive Coating

- High-Speed Tool Steel

- Emergency Stop, Protective Guarding

- Up to 150 mm diameter billets

- Hydraulic

- Integrated Water Cooling

- Fully Automatic with PLC Control

- Three Phase, 440V, 50Hz

- Floor Mounted

- High Throughput, Low Downtime

Product Description

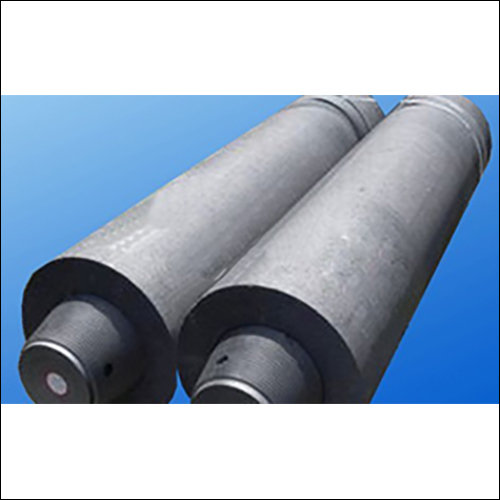

In the existing industry, we are highly engaged in presenting an exclusive range of Billet Auto Cutter. This is superiorly designed for cutting different kinds of billet in small sizes as per the requirements. The cutter is designed while using best in grade materials that is ideal for covering the risk of breakage. Depending on the reliable characteristics, this range is used for cutting of non ferrous materials like copper, aluminium and brass. Clients can buy this Billet Auto Cutter from us in different designs as per the needs.

Key features:

Key features:

- Automatic working

- Power efficient

- Superior performance

- Steel grade: Low carbon steel,low alloyed steel,stainless steel

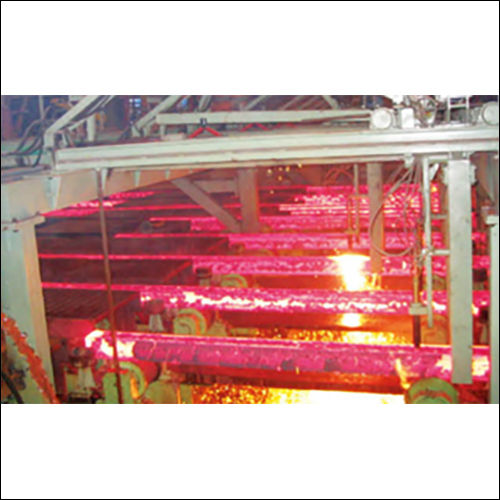

- Slab section: 90~32090~320mm

- Sizing dimension: 2500mm

- Lance cutting speed: 450mm/min

- Cutting seam: 8mm

- Max stroke of cutting trolley: 2500mm

- Lance max. return speed: 10m/min

Cutting Capacity and Precision

With the ability to slice billets up to 150 mm in diameter, this auto cutter delivers reliable, accurate cuts for a wide range of industrial metalworking applications. The high-speed tool steel blade ensures exceptional cutting efficiency and extended service life, even under continuous operation.

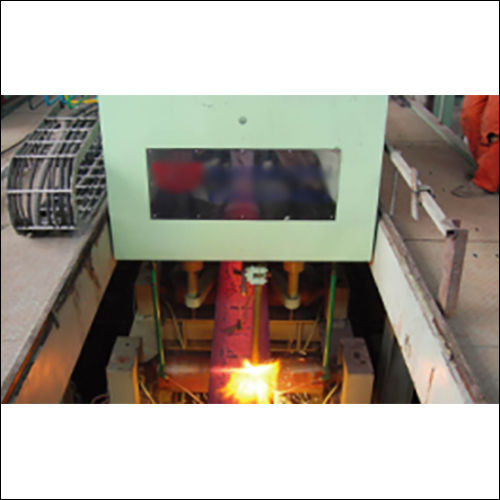

Automated Operation and Advanced Controls

A fully automatic system driven by PLC control minimizes manual intervention. Users benefit from seamlessly integrated hydraulic drive and water cooling, resulting in superior throughput and reduced downtime. The PLC provides precise control over the entire cutting process for consistent quality.

Safety and Durability

The billet cutter is equipped with emergency stop mechanisms and protective guarding to ensure operator safety. Its heavy-duty steel construction, painted surface, and anti-corrosive coating make it suitable for demanding industrial environments, offering longevity and low maintenance requirements.

FAQs of Billet Auto Cutter:

Q: How does the automatic billet cutter operate in an industrial metal cutting environment?

A: The billet auto cutter uses a fully automated PLC-controlled system combined with hydraulic drive and high-speed tool steel blades to efficiently cut billets up to 150 mm in diameter, minimizing manual labor and maximizing production speed.Q: What safety measures are integrated into the billet auto cutter?

A: Safety is ensured through emergency stop buttons and protective guarding around critical components, reducing the risk of accidents and maintaining a secure workspace during operation.Q: When should the billet cutters integrated water cooling system be used?

A: The integrated water cooling system operates continuously during cutting to regulate blade temperature and prevent overheating, especially during high-volume production runs.Q: Where is the billet cutter typically installed and used?

A: This cutter is designed for floor-mounted installation in manufacturing plants, fabrication workshops, and industrial metal cutting facilities where reliability and high throughput are required.Q: What is the process for operating and maintaining this billet cutter?

A: Operators set billet parameters through the PLC control, start the automated cutting cycle, and monitor system alerts. Routine maintenance involves checking the hydraulic drive, cleaning the cooling system, and inspecting the blade for wear.Q: How can users benefit from the billet auto cutters high production efficiency and low downtime?

A: Leveraging its fully automatic operation and integrated cooling and safety features, users gain consistent, high-speed cutting performance, resulting in increased production capacity and minimal interruptions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |