Bloom Auto Cutter

Product Details:

- Type Auto Cutter

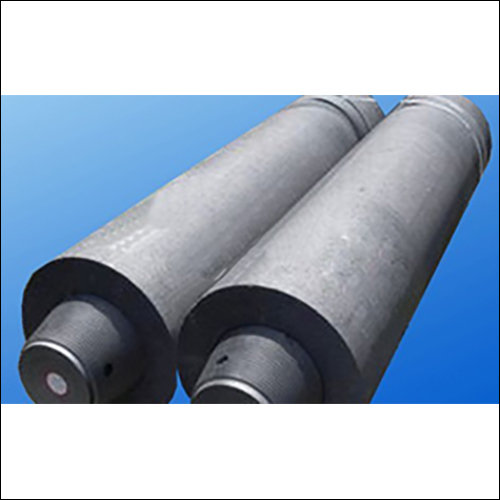

- Material Metal

- Application Industrial Cutting

- Click to View more

X

Bloom Auto Cutter Product Specifications

- Industrial Cutting

- Metal

- Auto Cutter

- Electric

- Bloom Auto Cutter

- 220V/50Hz

- Automatic

- Overload Protection, Safety Guard

- 450 mm x 320 mm x 310 mm

- High-Speed Steel

- Approx. 22 kg

- Silver/Blue

- User-friendly Interface

- Up to 200 sheets per pass

Product Description

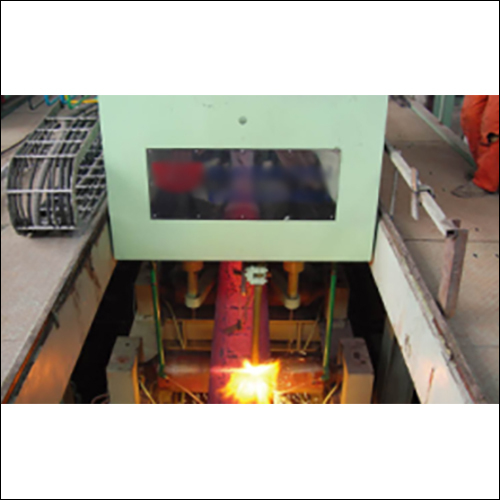

Offered Bloom Auto Cutter persuades with top quality cutting outcomes and in addition refined and strong plan. The item arrangement proposes two sorts of cutters adjusted to the necessities of the steel processes. In addition, one has cutting lights and is utilized for littler areas. Whereas, the other one has straight cutting light that is appropriate for wide sprouts or exceptional applications.

Key Features:

Key Features:

- Straightforward with pendulum drive

- High effectiveness water cooling instrument

- Enhanced cutting quality

- High operational accessibility

- Steel grade: Normal carbon steel, low alloyed steel,stainless steel

- Slab section: 90~300350~900mm90~700

- Sizing dimension: 2500mm

- Slab temperature: 700

- Type: Box single lance-automatic simultaneous type

- Total input power: 1.12Kw

- Wheel pitch: 800~1600mm

- Rail pitch :1000~1600mm

- Traveling speed : 0~12m/min

- Single lance cutting speed: 50~500mm/min

- Max stroke of cutting trolley: Slab width +100mm

- Cutting seam: 2~22mm

- Roughness of cutting surface: 1.5 mm

- Inclination of cutting surface: 1

Enhanced Efficiency for Industrial Environments

Bloom Auto Cutter stands out with its impressive cutting capacity, enabling users to process up to 200 sheets in one automated pass. The high-speed steel blade ensures sharp, consistent cuts, making this machine invaluable for busy production facilities and print shops. Built from metal, it can withstand rigorous industrial use.

User-Friendly and Safe Operation

Operating the Bloom Auto Cutter is straightforward thanks to its intuitive control panel. Safety mechanisms such as overload protection and a safety guard ensure secure operation, minimizing risks for workers. Its comprehensive design aims to maximize productivity while safeguarding users throughout the cutting process.

FAQs of Bloom Auto Cutter:

Q: How does the Bloom Auto Cutter enhance efficiency in industrial settings?

A: The Bloom Auto Cutter automates the cutting process, managing up to 200 sheets per pass, which significantly reduces manual effort and accelerates workflow. Its high-speed steel blade ensures rapid and accurate cutting, making it ideal for high-volume environments.Q: What safety features are integrated into the Bloom Auto Cutter?

A: This model is equipped with overload protection to prevent mechanical stress, as well as a safety guard that shields the user from the blade during operation, promoting safe working conditions.Q: When is the Bloom Auto Cutter most suitable for use?

A: It is most suitable for operations requiring frequent, high-capacity cutting, such as print shops, industrial suppliers, or manufacturers handling large batches of paper or similar materials regularly.Q: Where can the Bloom Auto Cutter be utilized?

A: The machine is designed for industrial and commercial facilities, including manufacturing plants, distribution centers, and trading companies where robust cutting equipment is essential.Q: What is the installation process and initial setup procedure for the Bloom Auto Cutter?

A: Installation involves positioning the cutter on a stable surface, ensuring adequate power supply (220V/50Hz), and following the manufacturers setup instructions for the control panel and safety features. Initial calibration may be necessary as per the user manual.Q: How is the Bloom Auto Cutter operated and maintained?

A: Operation is straightforward with the user-friendly control panel. To maintain optimal performance, regularly clean the blade, check for wear, and inspect safety mechanisms. Detailed maintenance guidelines are provided in the product documentation.Q: What are the primary benefits of using the Bloom Auto Cutter?

A: The primary benefits include enhanced productivity due to its automatic operation, reliable precision cuts, robust safety features, and a durable metal build designed for consistent industrial performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |