Graphite Electrode

Product Details:

- Type Graphite Electrode

- Material High-purity Graphite

- Application Steel making, Electric arc furnace, Foundries

- Click to View more

Graphite Electrode Product Specifications

- Steel making, Electric arc furnace, Foundries

- High-purity Graphite

- Graphite Electrode

- 1.5 - 2.2 10 /C

- 4.5 - 7.5 m

- 1000mm to 2400mm

- 0.5%

- ISO 9001 Certified

- 8.0 - 12.0 MPa

- RP/HP/UHP (Regular/High Power/Ultra High Power)

- 50mm to 700mm

- Widely used in ladle refining furnaces, non-ferrous metal smelting

- 1.55 - 1.85 g/cm

- 0.3%

- Grey to Black

- Cylindrical with threaded nipple

Product Description

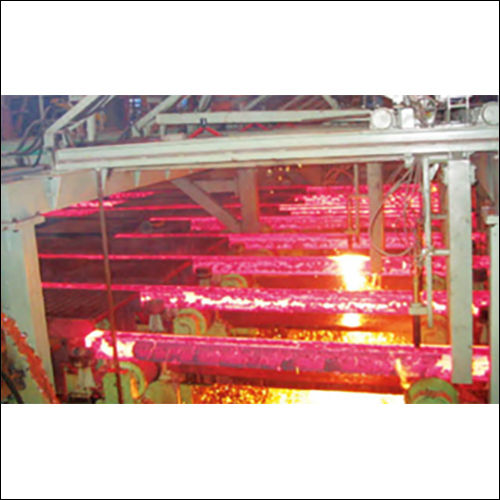

Focussing on the latest market developments, we are competent of presenting a quality driven range of Graphite Electrode. It is present as indispensable material required in the electric arc furnace steel making sector. Also, the offered range has the capability of sustaining the high levels of generated heat and vastly demanded to refine steel in furnaces and in different smelting processes. Generally, Graphite Electrode known for expulsing carbon that is produced by the process of carbonizination of materials in electric furnace at highest level of production.

Key features:

- Good mechanical property

- Excellent electrical conductivity

- Low thermal expansion

Physico-chemical Specifications of HD Graphite Electrode

| Item | Unit | Diameter (mm) | |||||||

| 75~200 | 250~400 | 450~600 |

| ||||||

| Grade A | Grade B | Grade A | Grade B | Grade A | Grade B |

| |||

| Specific | Pole | .m | 7.2 | 8 | 7.2 | 8 | 7.5 | 8.5 |

|

| Nipple | 6.8 | 6.8 | 6.8 |

| |||||

| Bending | Pole | Mpa | 10.0 | 9.0 | 8.0 |

| |||

| Nipple | 15.0 | 15.0 | 15.0 |

| |||||

| Youngs | Pole | Gpa | 12.0 | 12.0 | 12.0 |

| |||

| Nipple | 14.0 | 14.0 | 14.0 |

| |||||

| Bulk | Pole | G/cm3 | 1.6 | 1.6 | 1.6 |

| |||

| Nipple | 1.7 | 1.7 | 1.7 |

| |||||

| CTE | Pole | 10-6/ | 2.6 | 2.6 | 2.6 |

| |||

| Nipple | 2.3 | 2.3 | 2.3 |

| |||||

| Ash Content | % | 0.3 | 0.3 | 0.3 |

| ||||

Physico-chemical Specifications of HP Graphite Electrode

| Item | Unit | Diameter (mm) | |||||

| HP electrode | Type II of HP | ||||||

| 200~400 | 450~500 | 550~700 | 350~400 | 450~550 | |||

| Specific | Pole | .m | 7 | 7 | 7 | 6.5 | 6.5 |

| Nipple | 6 | 6.5 | 5.8 | 5.5 | 8.5 | ||

| Bending | Pole | Mpa | 10.5 | 10 | 10 | 10 | 10 |

| Nipple | 16 | 16 | 16 | 18 | 18 | ||

| Youngs | Pole | Gpa | 12 | 12 | 12 | 14 | 14 |

| Nipple | 16 | 16 | 16 | 18 | 19 | ||

| Bulk | Pole | G/cm3 | 1.62 | 1.62 | 1.62 | 1.63 | 1.63 |

| Nipple | 1.7 | 1.7 | 1.7 | 1.72 | 1.73 | ||

| CTE | Pole | 10-6/ | 2.4 | 2.4 | 2.4 | 2.2 | 2.2 |

| Nipple | 2.2 | 2.2 | 2.2 | 1.6 | 1.6 | ||

| Ash Content | % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

Physico-chemical Specifications of UHP Graphite Electrode

| Item | Unit | Diameter (mm) | ||||

| 300~400 | 450~500 | 550~600 | 550~600 | |||

| Specific | Pole | .m | 6.2 | 6.3 | 6.3 | 6.3 |

| Nipple | 5.0 | 5.0 | 4.5 | 4.5 | ||

| Bending | Pole | Mpa | 10.5 | 10.5 | 11.0 | 11.0 |

| Nipple | 18.0 | 18.0 | 20.0 | 22.0 | ||

| Youngs | Pole | Gpa | 14.0 | 14.0 | 14.0 | 14.0 |

| Nipple | 18.0 | 18.0 | 22.0 | 22.0 | ||

| Bulk | Pole | G/cm3 | 1.66 | 1.66 | 1.66 | 1.66 |

| Nipple | 1.73 | 1.74 | 1.75 | 1.78 | ||

| CTE | Pole | 10-6/ | 1.5 | 1.5 | 1.4 | 1.4 |

| Nipple | 1.4 | 1.4 | 1.2 | 1.2 | ||

| Ash Content | % | 0.3 | 0.3 | 0.5 | 0.5 | |

Superior Performance and Reliability

Our graphite electrodes provide consistent electrical conductivity and thermal stability for industrial applications. Precise specifications in diameter, length, and density ensure optimal arc performance during steel making and non-ferrous metal smelting. Manufactured to ISO 9001 standards, they deliver enhanced durability and a reliable connection, minimizing operational interruptions.

Versatile Applications Across Industries

These electrodes are extensively used in ladle refining furnaces, electric arc furnaces, and foundries. High-purity material and uniform cylindrical shape support various manufacturing processes, from heavy-duty steel production to specialized non-ferrous metal melting, suiting the needs of global distributors and manufacturers.

FAQs of Graphite Electrode:

Q: How are the graphite electrodes installed in an electric arc furnace?

A: Graphite electrodes are fitted into place by securing their threaded nipples to maintain a solid electrical connection. Proper installation is essential for stable current transmission and to minimize vibration during furnace operations.Q: What are the main benefits of using high-purity graphite electrodes with low ash content?

A: High-purity graphite electrodes with low ash content (0.3%) ensure clean melt processes, improved conductivity, and reduced contamination during steel production, resulting in higher quality end products.Q: When should I choose RP, HP, or UHP grade electrodes for my application?

A: RP grade is suited for standard operations, HP for higher power requirements, and UHP for intensive applications requiring maximum thermal and electrical conductivity, such as ultra-high temperature furnace operations.Q: Where are these graphite electrodes commonly used?

A: They are widely utilized in steel making plants, ladle refining furnaces, non-ferrous metal smelting facilities, foundries, and are distributed globally by manufacturers and suppliers, particularly from China.Q: What processes benefit most from graphite electrodes with high bending strength and low resistivity?

A: Processes such as steel manufacturing and electric arc furnace operations benefit greatly, as high bending strength ensures durability, while low resistivity provides efficient energy transfer for stable melting cycles.Q: How does ISO 9001 certification impact product quality and reliability?

A: ISO 9001 certification guarantees quality management and consistent production standards, assuring customers of product reliability, performance, and adherence to international benchmarks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |