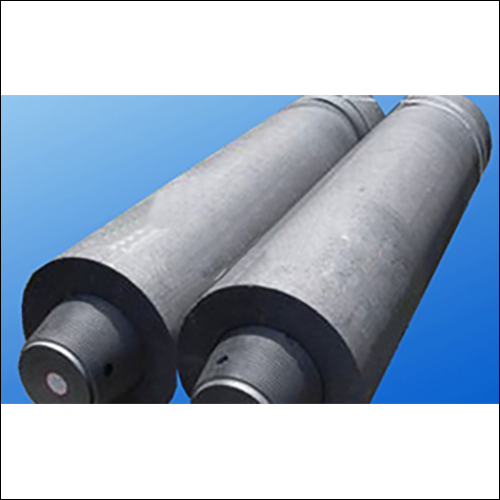

RP Graphite Electrode

Product Details:

- Type RP (Regular Power) Graphite Electrode

- Material High Quality Petroleum Coke and Needle Coke

- Application Electric Arc Furnace (EAF), Ladle Furnace (LF) Steel Making

- Click to View more

RP Graphite Electrode Product Specifications

- High Quality Petroleum Coke and Needle Coke

- Electric Arc Furnace (EAF), Ladle Furnace (LF) Steel Making

- RP (Regular Power) Graphite Electrode

- 3TPI, 4TPI, 4LPI

- 8.5 Mpa

- 0.5%

- 1.55 - 1.75 g/cm

- 75mm - 700mm

- 1200mm - 2700mm

- Wooden Box

- Steel production, smelting, refining operations

- 8.0 m

- 2.4 x 10/C

Product Description

Working with the collaboration with of our clients, we are competent of presenting RP Graphite Electrode. It is highly appreciated among our clients for its matchless qualities like high durability, reliable performance and quality. Good quality of graphite is used for the fabrication that is widely procured from trustworthy vendors of our clients. This electrode is highly required in steel making, ladle furnace and other industrial furnace for hassle free working. RP Graphite Electrode is easily accessible to our clients at economical prices.

Key features:

- Low electrical resistivity

- Good bending strength

- Anti shock performance

Technical Specifications

| Item | Unit | Diameter (mm) | ||||||

| 75~130 | 150~200 | 250~300 | ||||||

| Grade A | Grade B | Grade A | Grade B | Grade A | Grade B | |||

| Specific | Pole | .m | 8.5 | 10 | 9 | 10.5 | 9 | 10.5 |

| Nipple | 8.5 | 8.5 | 8.5 | |||||

| Bending | Pole | Mpa | 10 | 10 | 7.8 | |||

| Nipple | 14 | 14 | 15 | |||||

| Youngs | Pole | Gpa | 9.3 | 9.3 | 9.3 | |||

| Nipple | 14 | 14 | 14 | |||||

| Bulk | Pole | G/cm3 | 1.6 | 1.5 | 1.5 | |||

| Nipple | 1.6 | 1.6 | 1.7 | |||||

| CTE | Pole | 10-6/ | 2.9 | 2.9 | 2.9 | |||

| Nipple | 2.7 | 2.7 | 2.8 | |||||

| Ash Content | % | 0.5 | 0.5 | 0.5 | ||||

| Item | Unit | Diameter (mm) | ||||||

| 350 | 400/500 | 450 | ||||||

| Grade A | Grade B | Grade A | For silicon | Grade A | Grade B | |||

| Specific | Pole | .m | 9 | 10.5 | 9 | 11 | 9 | 10.5 |

| Nipple | 8.5 | 8.5 | 8.5 | 8.5 | ||||

| Bending | Pole | Mpa | 7 | 6.8 | 6.8 | 6.8 | ||

| Nipple | 15 | 15 | 15 | 15 | ||||

| Youngs | Pole | Gpa | 9.3 | 9.3 | 9.3 | 9.3 | ||

| Nipple | 14 | 14 | 14 | 14 | ||||

| Bulk | Pole | G/cm3 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Nipple | 1.7 | 1.7 | 1.7 | 1.7 | ||||

| CTE | Pole | 10-6/ | 2.9 | 2.9 | 2.9 | 2.9 | ||

| Nipple | 2.8 | 2.8 | 2.8 | 2.8 | ||||

| Ash Content | % | 0.5 | 0.5 | 0.5 | 0.5 | |||

Unmatched Performance in Steel Making

RP Graphite Electrodes ensure consistent and efficient electrical conductivity, making them ideal for high-demand steel production environments. Their robust construction supports reliable operation in electric arc and ladle furnaces, boosting productivity and minimizing downtime.

Advanced Material Selection for Superior Quality

Manufactured from premium petroleum coke and needle coke, these electrodes exemplify purity and stability. Low ash content and tight specifications guarantee dependable performance, even under rigorous smelting and refining conditions.

FAQs of RP Graphite Electrode:

Q: How are RP Graphite Electrodes utilized in steel production?

A: RP Graphite Electrodes serve as conductors in electric arc furnaces (EAF) and ladle furnaces (LF), facilitating the efficient melting and refining of steel by transferring high electrical currents needed for these processes.Q: What benefits do RP Graphite Electrodes offer over other electrodes?

A: RP Graphite Electrodes provide excellent electrical conductivity, high flexural strength, minimal thermal expansion, and exceptionally low ash content, resulting in stable performance, reduced energy consumption, and improved steel purity.Q: When should I choose RP Graphite Electrodes for my operation?

A: RP Graphite Electrodes are recommended for regular power applications in steel mills and foundries where consistent operation and moderate energy efficiency are required. They are ideal for EAF and LF usage scenarios.Q: Where are RP Graphite Electrodes commonly supplied from?

A: RP Graphite Electrodes are widely manufactured, exported, and distributed from China, recognized globally for its advanced production capabilities and competitive pricing in the graphite electrode market.Q: What is the process for installing RP Graphite Electrodes, including nipple types?

A: Before installation, choose the appropriate nipple type (3TPI, 4TPI, or 4LPI) to match the electrode threading. Securely join the sections and ensure electrodes are properly packed in wooden boxes to prevent damage during shipping and handling.Q: Can RP Graphite Electrodes be used for applications other than steel making?

A: While primarily designed for steel production, smelting, and refining operations, RP Graphite Electrodes can also be suitable for other metallurgical processes that require high-temperature electrical conduction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |