Three Dimensional Carbide Rolls

Product Details:

- Type Three Dimensional Carbide Rolls

- Material Carbide

- Application Wire Rod Mill, Rolling Mill

- Click to View more

Three Dimensional Carbide Rolls Price And Quantity

- Sintered with advanced processing

- Precision rolling, enhanced wear resistance

- Polished/Gray

- Three Dimensional

- High

- 14.6 g/cm³

- ±0.01 mm

- Excellent

- 150 mm to 400 mm

- 85-90

Three Dimensional Carbide Rolls Product Specifications

- Wire Rod Mill, Rolling Mill

- Three Dimensional Carbide Rolls

- Carbide

- Sintered with advanced processing

- Precision rolling, enhanced wear resistance

- Polished/Gray

- Three Dimensional

- High

- 14.6 g/cm³

- ±0.01 mm

- Excellent

- 150 mm to 400 mm

- 85-90

Product Description

Uniquely designed Three Dimensional Carbide Rolls are widely demanded among our customers for several applications. Our proposed range is idealized designed for reinforcement wire cold rolling and forming applications. As per the variegated demands of our clients, these rolls are designed with utmost precision while procuring the superior grade of materials and updated machine as per quality norms. Thereof, this range is required for its rib accuracy and clear marking. Three Dimensional Carbide Rolls are easily accessible at best market price.

Key features:

- Improve performance

- Enhance the strength

- High efficiency

Technical Specifications

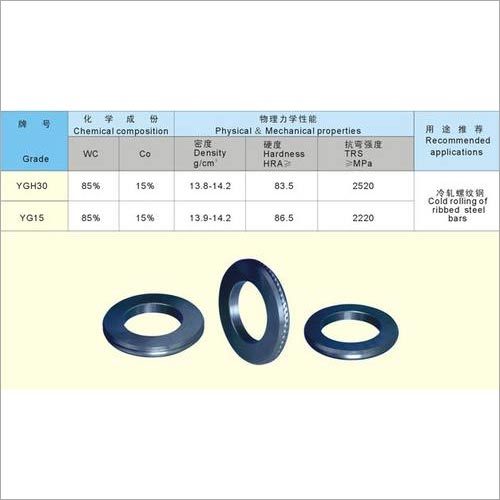

| Grade | Chemical Composition | Physical and mechanical properties | Recommended applications | |||

| WC | Co | Density g/cm3 | Hardness HRA > | TRS >MPa | ||

| YGH 30 | 85% | 15% | 13.8-14.2 | 83.5 | 2520 | Cold rolling of ribbed steel bars |

| YG15 | 85% | 15% | 13.9-14.2 | 86.5 | 2220 | |

Advanced Processing for Consistent Performance

Utilizing state-of-the-art sintering technology, these carbide rolls achieve remarkable uniformity and high integrity. Each roll undergoes strict quality checks to ensure optimal hardness and corrosion resistance, providing reliable operation even in demanding rolling environments.

Precision Rolling and Enhanced Wear Resistance

Engineered for wire rod mills and rolling mills, Three Dimensional Carbide Rolls deliver unparalleled wear resistance. Their robust construction and precise tolerance contribute to consistent, high-quality output, reducing downtime and maintenance costs for manufacturers.

Versatile Surface Finishes and Dimensions

Available in polished or gray surface finishes and a wide diameter range from 150 mm to 400 mm, these carbide rolls are suitable for diverse rolling applications. Their versatile design enables easy customization to meet specific operational requirements.

FAQs of Three Dimensional Carbide Rolls:

Q: How are Three Dimensional Carbide Rolls manufactured?

A: Three Dimensional Carbide Rolls are produced through advanced sintered processing, which involves compressing carbide powder and sintering it at high temperatures. This method ensures high density, superior hardness, and excellent corrosion resistance.Q: What applications can these carbide rolls be used for?

A: These rolls are specifically designed for wire rod mills and rolling mills, making them ideal for precision rolling tasks. They are suitable for environments that require enhanced wear resistance and extended service life.Q: When should I choose Three Dimensional Carbide Rolls for my production line?

A: Three Dimensional Carbide Rolls are best chosen when precision rolling, durability, and wear resistance are essential. They are especially beneficial for demanding, high-volume operations in the steel and metal forming industries.Q: Where are these carbide rolls available for distribution or supply?

A: These rolls are distributed, exported, and supplied across China and international markets by manufacturers, distributors, exporters, and traders, ensuring broad availability for industrial end-users.Q: What benefits do the rolls offer over conventional materials?

A: With a hardness rating of HRA 85-90 and density of 14.6 g/cm, these carbide rolls provide significantly increased wear resistance, impact strength, and corrosion resistance, resulting in longer tool life and less frequent replacement.Q: How precise are the dimensions and tolerances of these rolls?

A: Each roll is manufactured to exacting standards, with dimensional tolerances of 0.01 mm, ensuring the high precision required in modern rolling processes.Q: What options are available regarding surface finish and diameter?

A: Three Dimensional Carbide Rolls can be supplied with either polished or gray surface finishes and are available in diameters ranging from 150 mm to 400 mm, catering to various operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Spare Parts' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |