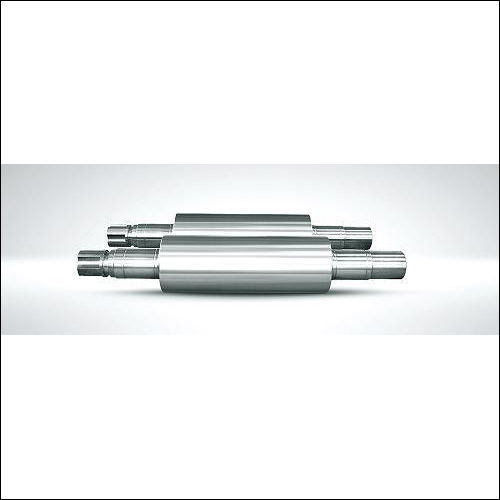

Non Continuous Carbide Rolls

Product Details:

- Diameter Up to 400 mm

- Capacity Heavy-duty industrial usage

- Material Tungsten Carbide

- Dimensions Custom-made as per requirements

- Technique High temperature sintering, precision grinding

- Standard DIN, JIS, ASTM, GB

- Belt Width Customizable as per application

- Click to View more

Non Continuous Carbide Rolls Product Specifications

- DIN, JIS, ASTM, GB

- Custom-made as per requirements

- High temperature sintering, precision grinding

- Customizable as per application

- Tungsten Carbide

- Heavy-duty industrial usage

- High wear resistance, precision performance, long operational life

- Up to 400 mm

- HRA 85-92

- Non-continuous grooved carbide roll

- Up to 0.01 mm

- Steel rolling mills, wire rod rolling, bar mills

- Steel or as specified

- Polished or as specified

- Suitable for high temperature applications

- Extended, depending on usage conditions

- 1 piece

- Wooden case or as required

- Excellent

- Metallic Grey

Product Description

Non Continuous Carbide Rolls (NCC)

As we are leading organization in the exiting market, we are proudly supplying a fault free range of Non Continuous Carbide Rolls. Our offered carbide rolls are widely required for milling applications as these perk up the wearability and impact resistance. Even under the rough rolling process, these rolls are used for promoting the fire cracking formation. These kinds of rolls are generally manufactured by making selection of good quality alloy along with special heat treatment. Our clients can purchase these Non Continuous Carbide Rolls in different specifications at best price.

Key features:

- Resistant against fire cracking

- Good strength

- Simple to use

Chemical Composition

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| NCC I | 3.00-3.40 | 2.00-2.50 | 0.80-1.00 | 0.15 | 2.00-3.00 | 0.40-0.70 |

| NCC II | 3.00-3.40 | 1.50-2.00 | 0.80-1.00 | 0.15 | 2.50-4.50 | 0.50-1.00 |

Prosperities & Application

| Symbol | Hardness | Tensile Strength | Bending Strength | Dimension | Unit N.W |

| NCC | 40-50 | 520 | 970-1380 | 500-1380 | 1000- 35000 |

| NCC | 50-60 | 520 | 970-1380 |

Exceptional Durability and Precision

These carbide rolls, boasting hardness ratings from HRA 85 to 92, deliver outstanding wear resistance and long operational life. Advanced high temperature sintering and precision grinding techniques ensure each roll meets rigorous industrial standards. Their ability to withstand continuous use in abrasive, high-temperature environments makes them a cost-effective investment for demanding steel rolling operations.

Custom-Made for Industrial Efficiency

Every non-continuous grooved carbide roll can be tailored in diameter (up to 400 mm), belt width, and surface finish as per your application requirements. This flexibility, combined with heavy-duty capacity and customizable core materials, enables our rolls to integrate seamlessly into different steel processing lines and deliver optimal operational efficiency.

FAQs of Non Continuous Carbide Rolls:

Q: How should non-continuous carbide rolls be installed and maintained in high-temperature steel rolling environments?

A: These carbide rolls are designed for heavy-duty, high-temperature settings and should be installed by experienced personnel. Regular inspection for wear, lubrication where necessary, and adherence to operational guidelines will help ensure optimal performance and extended service life.Q: What are the primary benefits of using non-continuous carbide rolls compared to conventional steel rolls?

A: Non-continuous carbide rolls offer superior hardness (HRA 85-92), exceptional wear resistance, and outstanding corrosion protection. This increases operational reliability, reduces downtime due to replacement, and ensures high-precision results in steel and wire rod rolling processes.Q: When should these carbide rolls be considered for replacement?

A: Replacement should be considered if dimensional tolerance exceeds 0.01 mm, if there is visible wear affecting performance, or at the end of their extended service lifetiming varies based on the intensity and conditions of use in steel rolling mills.Q: Where are non-continuous carbide rolls typically used?

A: These rolls are commonly used in steel rolling mills, wire rod rolling, bar mills, and other heavy-duty industrial environments requiring robust, high-temperature, and corrosion-resistant rolling tools.Q: What is the manufacturing process for these carbide rolls?

A: The rolls are produced using high-temperature sintering of tungsten carbide, followed by precision grinding to meet strict tolerance and surface finish specifications. This process ensures both structural integrity and high accuracy.Q: How does the customizable design of these rolls benefit industrial operations?

A: Custom dimensions, belt width, and core material allow each roll to fit specific machinery and process requirements, enhancing workflow efficiency and reducing the need for modifications or adjustments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rolling Mill Rolls' category

|

UNITED GLORY CORPORATION LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |